Solusi WWTP

Kami bermitra dengan:

Kugler Screw Presses

Screw Presses are effective, economical and ecological. Modern screw presses are well suited for large WWTP larger than 100.000 PE as their throughput per machine is up to 100 m³/hour.

Screw presses are ideal for drainage of:

- Sludge produced by biological municipal and industrial watewater treatment (activated waste sludge, primary sludge, digestate)

- Flotate sludge, from FOG removal

- Divers organic and inorganic sludge/waste streams

Screen-Press Series S-SK Series

The classic screen basket technology. Effective, durable and affordable.

The S-SK series is the most convenient entry-level model. It is equipped with a robust strainer basket, through which sludge is effectively dewatered both from sewage treatment plants and from industry. Wear, energy and personnel costs are considerably lower than with centrifuges, sieve belt or chamber filter presses with comparable drainage results.

Features| Sound dewatering results |

| Very low energy and water consumption, moderate consumption of polymers |

| Dewatering possible of sludges with 0.2% TS without prior thickening |

| Low wear (extended warranty possible), low maintenance, robust |

| Self-cleaning (24 hour operation possible), easy to operate, low noise, and no vibration |

| Polymer preparation units available upon request |

| Throughput up to 20 m³/hour digestate (5% TS), or 100 m³/hour thin sludge (0.2% TS) |

| Makes investing into own sludge dewatering feasable—sludge can be dewatered without anaerobic thickening (NH-4 contamination) |

| Kugler can offer two alternatives: screw presses with self-cleaning ring-technology; or classic screening basket technology |

Ring-Press Series S-RS Series

The S-RS series is suitable for sludge from sewage treatment plants and industrial production (including grease/oil sludge). It achieves a good and stable drainage result—with up to 90% less time spent, water and electricity than centrifuges, wire belt or chamber filter presses.

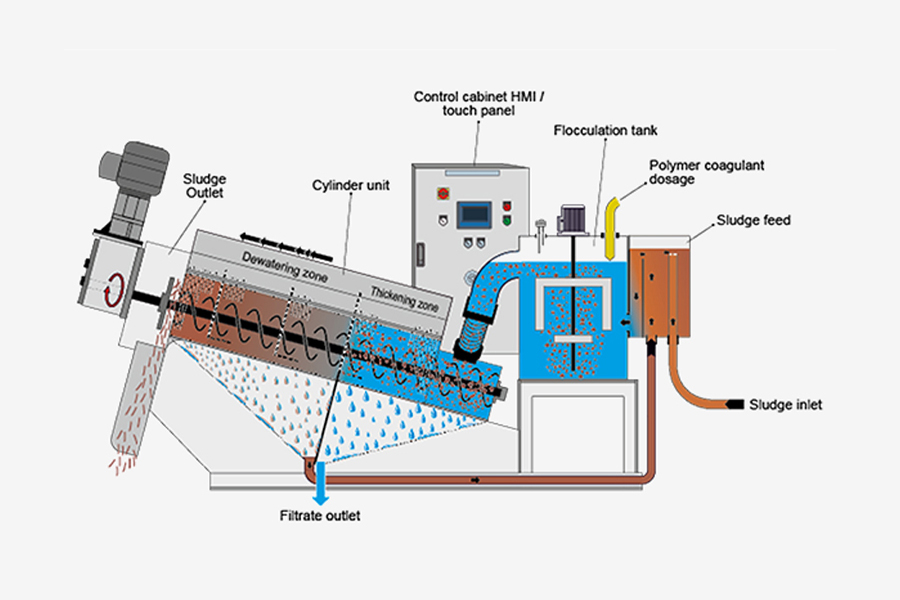

Functional principleRing-type screw presses are equipped with a self-cleaning mechanism and do not need high-pressure water cleaning, compressed air or brushes. That means lower maintenance as well as lower energy and water demand than screw presses with screening basket have. Due to the possibility to combine various parallel working modules in one system, this system needs less space than screw presses equipped with a screening basket.

After flocculation of the sludge, it flows by gravity into the press-cylinder and is being transported by means of a screw through the filtration element which consists of moving rings.

At the same time, the rotation of the screw moves the rings against each other. Each second ring will open a small space through which the free water drains. Because of the movement of the rings, a blocking of the filtration area is impeded and the necessity for cleaning is minimalized. The size of the openings between the rings decreases towards the press plate at the end of the screw. Thus, the inner pressure within the dewatering zone is increased (volume-compression-effect)

| Space saving |

| Moderate investment costs, low operating costs |

| Very robust—also in case of greasy sludges |

| Our models with integrated floc-former can increase the TS-concentration by 2–3% |

Untuk informasi lebih lengkap, berkonsultasi atau pemesanan produk, hubungi customer service kami:

(021) 2222-1627